Product Recovery (Pigging) Case Study on honey Manufacturing

How Multiple HPS Pigging Systems Are Tackling Product Waste, Energy Inefficiencies, and Batch Processing Challenges at a UK Honey Facility.

Summary

- HPS worked with a UK based honey company to tackle issues related to product waste, energy inefficiencies, and batch processing challenges at one of their facilities.

- Over the years, HPS has designed, installed, and commissioned 20 automated pigging systems across key sections of the plant, including from super melt cap to storage tank, and from storage tank to filler.

- By eliminating the need for heated or jacketed lines, the pigging systems have resulted in significant energy and cost savings, lowering electricity usage and reducing operational expenses.

- The systems also increase production capacity, allow for faster batch changeovers and enable the processing of multiple honey products on the same line without cross-contamination.

- Automating the pigging process has improved safety, minimised human error, and enhanced product traceability, contributing to better overall operational efficiency.

- HPS’s ongoing support, including staff training and technical assistance, ensures that the honey company continues to benefit from the long-term reliability and optimal performance of the pigging systems.

ABOUT THE COMPANY

The customer is a major player in the food industry, representing a diverse portfolio of well-known consumer brands. With a focus on various product categories such as snacking and sweet treats, health and wellness, and baking and meal Ingredients, the company holds a strong position in the market.

One of their standout brands is a popular honey product line, which holds a top position in its category and is well-recognised by consumers. This brand offers a variety of honey products as well as other sweet and spreadable goods like pure maple syrup, lemon curd, and dessert sauces. These products are widely distributed across retail, wholesale, foodservice, pharmacy, and manufacturing channels.

With over 300 product lines and a production capacity of approximately 26,000 tonnes of honey per year, the company has experienced significant growth, doubling sales over the past decade.

This case study details the challenges faced at their processing plant, where the team encountered issues with product waste and batch processing efficiency.

why the company chose hps as their pIGGING SYSTEM PROVIDER

HPS Advanced Liquid Product Recovery Technology, commonly known as “pigging,” is a highly efficient, automated solution used by liquid product manufacturers to recover valuable product from pipelines for further processing, packaging, and sale.

The benefits of implementing pigging systems are substantial. Pigging systems increase product yields and production capacity, minimize the risk of cross-contamination, and enhance environmental sustainability by reducing waste and cleaning requirements.

The client chose HPS for this project due to their extensive expertise and proven track record in deploying pigging systems across a range of industries, particularly within the food sector. HPS’s ability to deliver customized solutions, coupled with their strong commitment to quality and ongoing customer support, positioned them as the ideal partner.

In addition, HPS’s experience working with major food manufacturers such as Nestlé, Kraft, Unilever, and Mars further underscores their capabilities and credibility in the industry.

The Solution

Over the years, HPS has worked closely with the customer to design, supply, install, and commission a total of 20 pigging systems at their UK facility. These systems, tailored to their specific needs, are fully automated, single-pig systems which optimize product recovery and improve operational efficiency.

The pigging systems are installed across two key sections of the facility:

- Melting facility to storage tank

- Storage tank to filler

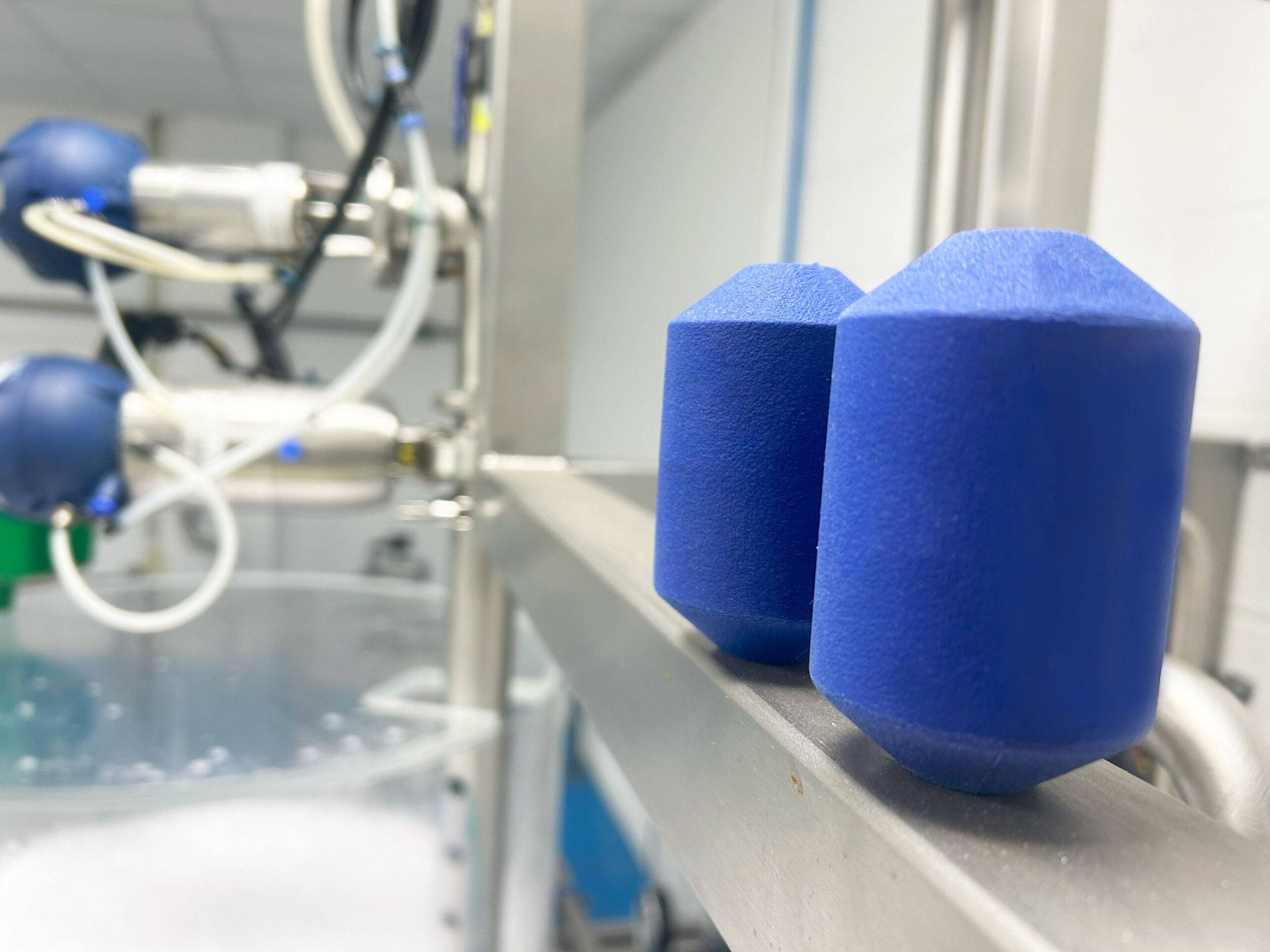

HPS implemented a variety of system components, including hygienic sanitary pigs, ball valves, AccuTect pig detectors, and control systems, all of which are controlled via an HMI interface.

The systems accommodate line sizes ranging from 2” to 4” in diameter, ensuring compatibility with their diverse production requirements. The fully automated nature of the systems allows for seamless operation and flexibility in processing different types of honey without the risk of product cross-contamination.

Each system installation at the UK facility includes:

- Single-pig systems for optimized product recovery

- Hygienic ball valves for clean and efficient pigging

- Advanced AccuTect pig detectors to ensure smooth operation

- HMI-controlled interfaces for easy system management and monitoring

HPS engineers commissioned the systems, as well as providing full training to the company’s staff to ensure they could safely and effectively operate and maintain the equipment.

The strong relationship between HPS and the UK honey company continues, with HPS providing ongoing customer support and technical advice as needed.

The Results

The installation of HPS pigging systems at the UK honey facility has delivered significant benefits across multiple areas of their operations.

One of the most impactful outcomes is the reduction in product waste, as the pigging system enables the recovery of nearly all residual honey from pipelines, saving it from being discarded or downgraded. This prevents different grades from being reworked into lower-quality products or sent to waste.

The pigging systems have drastically sped up batch changeover times by roughing 90%, allowing the company to process multiple honey products on the same line without the risk of cross-contamination.

The pigging systems have also eliminated the need for heated or jacketed lines, significantly reducing installation costs and ongoing energy consumption. This results in lower electricity bills and reduced operational costs, enhancing the facility’s overall sustainability.

In terms of efficiency, the pigging systems have drastically sped up batch changeover times significantly, allowing the company to process multiple honey products on the same line without the risk of cross-contamination.

This not only increases production capacity but also enhances the facility’s flexibility, eliminating the need for dedicated lines for different products.

Moreover, by automating the product recovery process, the company has improved safety by minimizing manual intervention, reducing the risk of human error, and ensuring consistent product traceability. The system has streamlined operations, enabling the plant to meet demand more efficiently while maintaining high product quality.

Overall, the HPS pigging solution has boosted production yields, increased sustainability, enhanced safety, and contributed to significant cost savings for the honey company.

Find Out More

Pigging systems deliver a wide range of benefits, from maximising product recovery and reducing waste, to cutting changeover times and improving sustainability.

See how leading brands are already gaining these advantages – explore our pigging system case studies and discover the results for yourself.

If you’re ready to improve the efficiency, profitability, and sustainability of your liquid processing, contact your nearest HPS office today.