Process Pigging Technology

HPS provides Advanced Liquid Product Recovery (Pigging) Technology that recovers residual product from process pipelines. Trusted worldwide, our technology increases yield, reduces changeover times, and enhances operational efficiency.

Process Perfected

Why Pigging systems?

HPS are the leaders in Advanced Liquid Product Recovery – a specialist form of pigging technology. With over 30 years of experience, we help companies significantly improve efficiency, capacity, sustainability, and profitability.

Pigging recovers product that would otherwise be wasted during processing. It’s a proven way to increase yield, reduce downtime, and cut energy, water, and cleaning fluid usage.

High ROI YEAR-ON-YEAR

HPS pigging systems pay for themselves fast, often in just a few months, through product savings alone. And the long-term returns continue year after year.

DESIGNED around your needs

Every system is designed around your specific products, processes, and goals. Whether you’re processing chocolate, soft drinks, paint, pet food, chemicals or cosmetics, HPS has the experience and technology to help.

PROVEN SUCCESS

0 +

years’ experience of successful systems implementation.

0 +

Customers around the world

0 +

Pigging and liquid transfer solutions installed

Some of Our Core Solutions and Services:

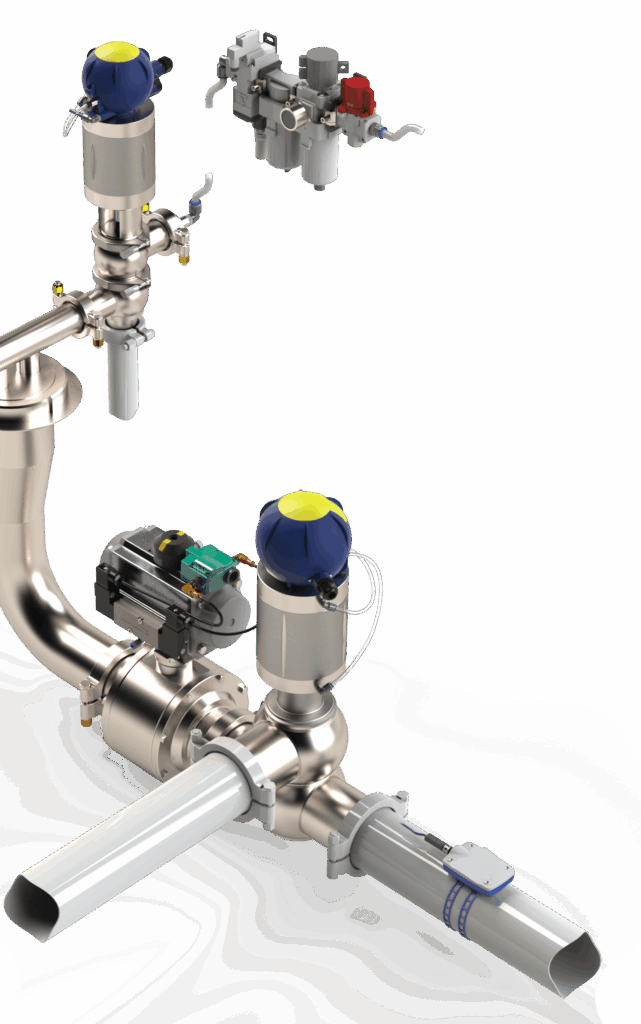

Pigging Systems

Fully automated, HPS hygienic (sanitary) pigging systems rapidly recover nearly all the residual product in pipelines during batch changeovers. Also known as pipeline product recovery systems, pigging increases efficiency, reduces waste, and improves sustainability.

Learn More About Pigging

Liquid Transfer Routing Solutions

HPS liquid transfer routing systems help companies to efficiently and safely transfer liquids from multiple sources and multiple destinations. Often used in combination with pigging technology, they’re ideal for food, beverages, cosmetics, chemicals, and more.

Liquid Transfer Routing Solutions

Equipment and Services

In addition to pigging systems, we also provide a range of additional products and services. These include specialist valves, pigging system design, as well as automation and control systems programming, training, support and much more.

Equipment and Services

Aftercare and Spares Service

HPS supports your system for the long term. From hygienic pigs, detectors, and seal kits to advice, diagnostics, and fast-response support – our team ensures your system runs smoothly and reliably.

Explore Aftercare and Spares

Industries We Serve

Our state-of-the-art automatic pigging and liquid transfer solutions improve production for:

- Ready Meals & Sauces

- Chocolate & Confectionery

- Soft Drinks & Beverages

- Wines & Spirits

- Pet Food

- Cosmetics & Personal Care

- Toothpaste & Gels

- Paints, Solvents & Varnishes

- Household Liquids

- Chemicals

- Lubricants & Slurries

- And Many More

We have a saying at HPS: “If You Can Pump It, We Can Pig It!”

Benefits of Pigging

Why You Should Consider Pigging Systems

High Return on Investment (ROI)

If you choose an HPS pigging solution, your savings will pay back the initial cost of the system in a few months and increase your profits for many years after that.

Increased Product Yields

Because pigging recovers nearly all residual product in pipelines instead of it being wasted, it significantly increases your product yield.

Sustainability

Pigging cuts waste, reduces water usage, lowers chemicals and related transport and disposal costs, making the environmental benefits of pigging significant.

high roi, waste reduction

More information

about pigging

HPS hygienic (sanitary) pigging systems deliver an exceptional return on investment (ROI) by recovering valuable product that would otherwise be lost between batches. What’s typically discarded becomes profit – with most systems paying for themselves in just a few months.

By significantly reducing changeover times (from hours to minutes) pigging boosts productivity while cutting operational costs. It also lowers consumption of energy, water, cleaning fluids, and reduces effluent, driving savings that continue long term.

Pigging helps you meet your sustainability goals by minimising waste and reducing environmental impact.

It also decreases the need for CIP cycles and flushes, lowering contamination risks and improving batch control and process efficiency.

“HPS Pigging Technology reduced our changeover times from around 3 hours to just a few minutes.”

Pigging System Case Study

Improving Efficiency and Cutting Waste

HPS pigging technology delivered impressive results for this manufacturer:

- Sanitisation times reduced from 2–3 hours to just 15 minutes.

- An 83% decrease in washout times.

- Waste cut by 93% compared to using IBCs.

- Minimal effluent disposal required.

- Fast and reliable changeovers and transfers.

HPS systems help companies save time, reduce waste, and increase productivity.

Latest from HPS

Chocolate and Confectionery

Keep Chocolate Moving: Preventing Solidification in Transfer Pipelines

HPS Company News

HPS 2025 Wrapped: Highlights, Insights and Milestones

Pigging and Liquid Transfer Technology

Exclusive Workshop Recording Now Available: Increasing Yields and Reducing Waste in Liquid Processing