Pigging technology for food and beverages

Stop Flushing Valuable product Away – Start Recovering It

Hidden losses are costing food and beverage manufacturers more than they realise – lost product, inefficient processes, and missed sustainability targets.

HPS Advanced Liquid Product Recovery ((which is a type of ‘pigging’ technology) recovers up to 99.5% of valuable product from pipelines, helping you reduce waste, save time, and improve profits.

- Recover More Product: Save up to 1,200 gallons per cycle by reclaiming usable product that would otherwise go down the drain

- Reduce Downtime and Costs: Cut sanitisation times from hours to minutes, shorten changeovers, and reduce cleaning-related expenses

- Improve Sustainability: Save millions of litres of water annually and lower your energy usage and carbon footprint.

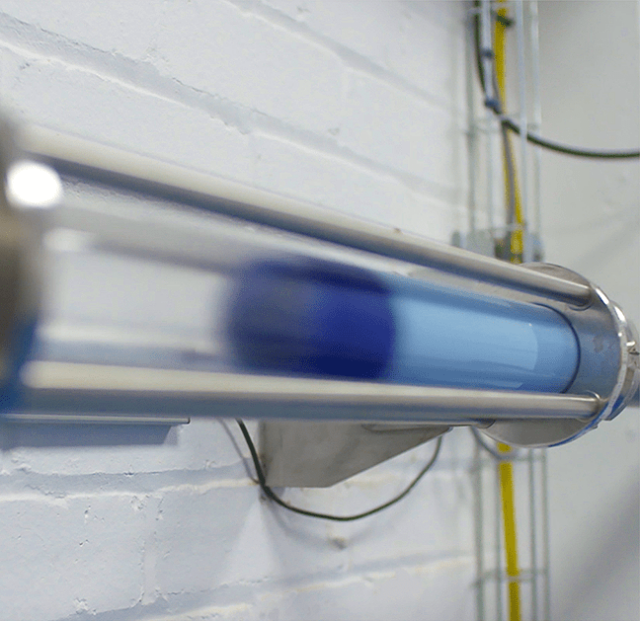

what is pigging technology?

Pigging (also known as liquid product recovery) uses a specialist projectile (called a “pig”) to safely push remaining product from the inside of pipelines. It’s fast, hygienic, and highly effective.

HPS pigging systems are:

- Fully automated and safe for food use

- Custom-engineered to fit your production needs

- Suitable for a wide range of products, from sauces and syrups to juices and spirits

Plug the Four Costliest Leaks in Your Process

Even the best-run facilities suffer from hidden inefficiencies. HPS systems target and eliminate four of the most damaging leaks in your production line:

-

1. Profit Leaks

Stop throwing money down the drain. Our systems recover nearly all residual product from pipelines, so you can sell it, not flush it.

-

2. Efficiency Leaks

Shorten changeovers, reduce clean-in-place (CIP) times, and increase uptime. That’s less downtime and lower labour costs.

-

3. Sustainability Leaks

Minimise water, chemical, and energy use. One customer saved 40 megalitres of water annually while cutting emissions and effluent treatment costs.

-

4. Competitive Leaks

Don’t get left behind. Pigging systems provide a competitive edge by improving cost control, product quality, and responsiveness to changeovers.

Why Choose HPS Pigging Systems?

With over 30 years of experience and 2,000+ successful installations, HPS is the trusted leader in hygienic pigging solutions.

✔ Fast ROI – Immediate cost savings and long-term profitability

✔ Industry-Leading Recovery – Up to 99.5% product recovery from pipelines

✔ Proven Success – Used by leading food, beverage, paint, coatings, and personal care brands

✔ Custom Solutions – Designed for your unique production process

Proven Success Across Multiple Industries

Manufacturers trust HPS to deliver measurable results, and our customers experience immediate financial and operational improvements.

Food Manufacturer

- Problem: Lost over 1,200 gallons of product per batch during flushing.

- HPS Solution: Recovered nearly all residual product.

- Outcome: Millions saved annually and environmental impact reduced.

Global Beverage Leader

- Problem: Changeovers took hours, leading to high downtime and lost productivity.

- HPS Solution: Installed automated pigging system.

- Outcome: Changeovers now take minutes, improving production capacity and ROI.

Chocolate Manufacturer

- Problem: Significant product loss and rework due to batch cross-contamination during changeovers

- HPS Solution: Streamlined processes with pigging.

- Outcome: HPS reduced rework to under 1%, saving the manufacturer around £2 million annually.

Ready to Stop Hidden Losses? Let’s Talk

Whether your priority is yield, efficiency, sustainability (or all three), HPS pigging systems deliver results. Backed by industry-leading engineering and decades of success, our solutions help food and beverage companies enhance their liquid processes.

- ✅ Low-risk, high-return investment

- ✅ Custom-designed for your production line

- ✅ Fully supported by HPS experts