When pipelines aren’t cleared efficiently between batches, valuable product is wasted, water and energy bills rise, and contamination risks increase.

This is a challenge faced by manufacturers across industries such as food and beverages, chemicals, paints, cosmetics, personal care, and household products.

The three most common methods for clearing pipelines are:

- Flushing with water or cleaning solutions

- Air purging with compressed air

- Pigging systems (liquid product recovery using a specialist projectile, or “pig”

There are also other approaches, such as ice pigging and vortex systems, which we’ve covered previously in our Alternatives to Traditional Hygienic Pipeline Pigging blog.

While all three methods remove residual product, they vary greatly in effectiveness, efficiency, sustainability, and hygiene standards.

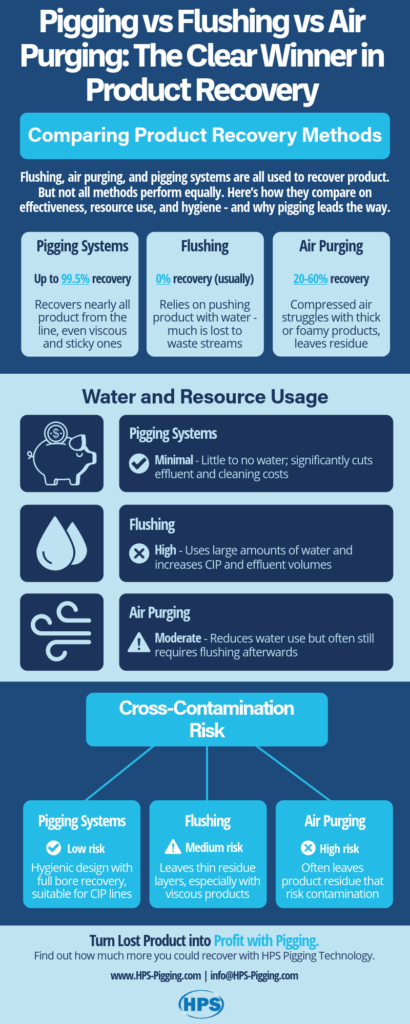

To make the differences clearer, we’ve created a Pigging vs Flushing vs Air Purging infographic.

In this blog, we’ll break down those comparisons in more detail, add additional factors such as time, cost, and environmental impact, and explain why pigging is usually the best choice.

Effectiveness at Recovering Product

Flushing: Recovery rates are low – flushing is usually performed to remove (not recover) product, and usually, most of it goes to drain as effluent. Significant product is lost because it mixes with water or cleaning solution.

Air Purging: Recovery rates range between 20–60%, but it leaves significant residue, especially with viscous or foamy products. Long, time consuming flushes are usually still required after air purge.

Pigging: Recovery rates are up to 99.5%. The pig pushes nearly all the product through, even sticky or thick liquids. The pigging operation is usually automatic and extremely quick. If flushes are still required, these are also short as only a trace of product is left in the line.

Why it matters: With higher tariffs, rising raw material costs, and tighter margins, every litre of product counts. Pigging helps manufacturers protect profitability by recovering nearly all of their product – quickly, effectively and efficiently.

Water and Resource Usage

Flushing: Requires large volumes of water, chemicals, and energy. Generates high wastewater volumes. There is often a tendency for operators to ‘over flush’.

Air Purging: Reduces water usage but often still requires long, water-intense flushing afterwards. Safety precautions may be required regarding safely channeling excess air within a factory environment.

Pigging: Reduces water and energy usage considerably. In some applications, a flush may still be required for final cleaning, but because pigging removes the majority of product first, water, chemicals, and energy use are significantly lower.

Why it matters: With rising utility costs, tightening environmental regulations, and increasing pressure on manufacturers to meet sustainability targets, reducing water and energy use is critical. Pigging helps companies control costs while improving their environmental performance.

For a more detailed breakdown of these differences, see our article where we compared Pigging with Flushing.

Cross-Contamination Risk

Flushing: Medium risk. Product residue can remain, especially with viscous products.

Air Purging: High risk. Traces of product frequently remain, raising contamination risks

Pigging: Low risk. The hygienic design and full-bore recovery leave pipelines almost product-free before CIP or sterilisation.

Why it matters: In highly regulated sectors like food, beverages, and personal care, avoiding contamination and product recalls is critical. Pigging offers greater assurance of product safety and integrity.

Infographic: Pigging vs Flushing vs Air Purging

Time and Changeover Speed

Flushing: Time-consuming, especially with large pipelines and long CIP cycles.

Air Purging: Faster than flushing but still requires additional cleaning.

Pigging: Significantly reduces changeover times, because most product is removed quickly and efficiently.

Why it matters: Faster changeovers mean less downtime and more production capacity – a crucial advantage in competitive, high-demand market.

Cost and ROI

Flushing: Low upfront cost, but expensive in the long run due to wasted product, high water use, and downtime. Over-flushing is a common problem, adding additional time, resources and effluent (and associated costs).

Air Purging: Moderate cost, energy-intensive, limited return. Any savings are offset by lower recovery rates, disposal costs, flush times and contamination risk.

Pigging: Higher initial investment, but rapid payback through effieint product recovery, reduced cleaning costs, and faster changeovers.

Why it matters: In today’s climate of rising costs and tighter margins, manufacturers need solutions that save money long term. Pigging delivers a clear and measurable ROI.

Suitability Across Products

Flushing: Works for simple, low-value, or water-compatible products. Inefficient, often relying on operator judgement.

Air Purging: Limited to less viscous products; not effective for sticky, foamy, or high-value liquids.

Pigging: Suitable for a wide range of applications, from syrups, sauces, and wines to paints, resins, shampoos, and household cleaners.

Why it matters: Plants processing multiple products on the same line need flexibility. Pigging supports varied product ranges without compromising hygiene.

Environmental Impact

Flushing: Heavy water use, high effluent volumes, and significant energy consumption.

Air Purging: high energy use but lower water usage. Cleaning steps still create waste.

Pigging: The most sustainable option, minimising water, chemical, and energy use while cutting waste streams.

Why it matters: Companies are under growing pressure to meet sustainability targets. Pigging offers a practical way to reduce environmental impact while improving efficiency.

Real-World Example

What looked like a simple solution was actually costing one beverage manufacturer thousands of litres of product every week.

Although air purging seemed inexpensive upfront, it only achieved around 10% recovery in this particular application. The hidden cost was huge amounts of wasted product and revenue.

By switching to an HPS pigging system, recovery rates increased to 99.5%, eliminating unnecessary waste and quickly paying back the investment. We’ve detailed this project in more depth – See the HPS beverage manufacturer case study.

Takeaway: Low-efficiency methods may seem cheaper, but the hidden cost of lost product adds up fast.

The Clear Winner

Flushing and air purging may be common, but they fall short in key areas such as product recovery, water efficiency, and hygiene. Pigging, by contrast, consistently delivers:

- Maximum recovery (up to 99.5%)

- Minimal water, chemical, and energy use

- Low cross-contamination risk

- Faster changeovers

- Automation and reduced labour costs

- High ROI and broad product suitability

For manufacturers under pressure from rising tariffs, increasing raw material and energy costs, and sustainability demands, pigging is the most effective, efficient, and future-ready solution.

Learn More

Our Pigging vs Flushing vs Air Purging infographic provides a quick, visual snapshot of these comparisons.

If you’d like to explore how pigging could improve efficiency in your plant, talk to our experts today.

Contact HPS for a free consultation or ROI assessment.