How to Calculate Return on Investment from a Product Recovery (Pigging) System

Pigging system payback and roi – It Will Save You More Than You Think….

Regardless of the scale of your business, ensuring a favourable return on investment (ROI) for capital purchases is crucial. This principle applies equally to buying a product recovery or pigging system.

Pigging systems have many clear benefits, including higher yields, waste reduction, faster changeover times, improved plant capacity and generally making life a lot easier. Properly designed and installed by experienced pigging providers, a pigging system will enhance the efficiency of your liquid processing operations and pay for itself extremely quickly.

However, as with any project, you need to quantify the savings you expect to make and calculate your pigging and product recovery system ROI as accurately as possible.

It’s worth noting that a pigging system has the potential to generate even greater savings than initially anticipated.

Start with our pigging system Savings Calculator

Maximising return on investment (ROI) and realising substantial savings are paramount objectives for any pigging system. The efficient recovery of product not only contributes significantly to cost reduction but also forms the basis of the figures shown by the HPS pigging system savings calculator. This invaluable tool serves as an excellent starting point when working out pigging system savings, pigging system payback and ROI.

It will give you a quick, easy and reasonably accurate estimate of how much a pigging system could save your business in terms of the value of product you are likely to recover every time you pig your system.

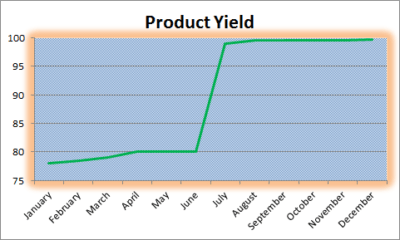

Product Recovery Increases Yield

When properly designed and implemented, a hygienic and sanitary product recovery system will save nearly all the product you would have previously disposed of. So, rather than being washed down the drain, sent to a waste collection area, waste treatment facility or similar, you can continue to process, use, package, store or sell your perfectly good product and increase your profits. It will be in the same condition as the rest of the product in the pipe: unaltered and uncontaminated.

It’s important to note that very few pigging systems (if any) can recover 100% of the product. This limitation often stems from design constraints, such as the location of pig launchers or receivers, resulting in a tiny amount of product that cannot be recovered. Nevertheless, HPS pigging solutions consistently excel in this regard, typically recouping up to an impressive 99.5% of the product.

Other Considerations When Estimating ROI

While the pigging system savings calculator is a great tool to get started and give you a handy cost estimate of product recovery system ROI, every pigging system is different. More importantly, there are several areas in which product recovery and pigging solutions can save you money and benefit your organisation that may not be so obvious. To accurately work out return on investment to justify your purchase and expenditure, it’s important to take all of these factors in to account and include them in any detailed investment calculations.

Numerous businesses already have established methods for determining payback time and ROI. So rather than go in to different calculation methods, here are some tips, ideas and recommendations of the areas you should think about and take into account when estimating the savings and calculating the return on investment. These guidelines are equally relevant whether you’re implementing a new plant or integrating pigging systems into existing pipelines or processes.

Savings from the Pigging Process

A good quality, well-designed and correctly implemented pigging system will significantly reduce the amount of product that is normally wasted. While this is of course an important part of your product recovery system ROI calculations, waste is not just the volume of product lost. Waste also includes the fluid used to evacuate the product and the power consumed in making this happen. What’s more, the waste will also need to be treated. Some products need more treatment than others. Whatever the product is, to a greater or lesser degree the cost of waste treatment will include chemical, transport, power and human resources.

Quicker, More Effective Cleaning

Pipeline product recovery reduces cleaning times, and the subsequent savings in staff time can be substantial. For instance, with highly viscous products, manual cleaning of a pipe can be an extensive process, often taking many minutes, or even hours, to achieve thorough cleanliness. Additionally, this manual cleaning process may consume significant quantities of water or cleaning fluid.

A pigging system can swiftly recover nearly all the product from a pipe in just a matter of seconds. This leaves your staff free to focus on tasks of greater significance and productivity, ensuring your processing continues with minimal disruption. Pigging and CIP go hand in hand, because as well as saving time, it also saves on power, water, detergents or other cleaning products. A further benefit is that in some circumstances, for example where there’s no significant change in colour, flavouring, fragrance, ingredients or similar, pigging may eliminate the need for washouts or secondary cleaning altogether.

Faster Batch Changeovers

Because pigging is much quicker and more effective than manual cleaning or manual product recovery processes, it significantly reduces batch changeover times. This increases available production time, reduces power and enables your staff to perform other tasks. So, if possible, you should add these to your product recovery system ROI calculations.

Pigging Removes Cleaning Residue Which Increases Efficiency

Even when you’ve cleaned a system using a washout method, it is often necessary to run your product through it for a while until it is no longer diluted by the water or cleaning fluid. Depending on the product, the amount you need to run off before the product is within specification for use, filling or storage can be substantial.

However, if you pig the system after cleaning (whether this was by washout or clean in place), it will remove water and cleaning fluid residue. This prevents product dilution or contamination at the start of a new product batch. Once again, pigging saves product, reduces waste and increases efficiency.

Pigging Prevents Aeration Problems

Certain products are susceptible to issues like foaming, aeration, or oxygen pickup, especially during the initiation of a new batch process. HPS has worked with many organisations to successfully eliminate foaming and aeration problems in liquid processing. One of the most effective ways of preventing aeration and related issues is by using a Double Pig System.

This ensures your product will be uncontaminated by air and within specification when it reaches its process destination. So if aeration is a current or potential issue in your production process which pigging will eliminate, it is important to include the efficiency gains and waste reduction savings in your product recovery system ROI calculations.

Reduces Pipe Maintenance

Pigging pipelines does more than just transfer and recover product. In many processes, pigging will maintain your pipe integrity by preventing material build up on the pipe walls. Without pigging, it may be necessary to shut down the process from time to time and clean the pipes manually.

As well as the cost of downtime, this also incurs labour costs. Depending on the pipe material and products, it could even need a replacement pipe. Therefore, pipe maintenance reduction is a further consideration when calculating pigging system ROI.

More Environmentally Friendly

Most companies take their environmental responsibilities extremely seriously. The environmental benefits of pigging are well established, and by reducing waste, using less water and cleaning fluids, decreasing power consumption and increasing overall process efficiency, HPS Product Recovery Solutions can go a long way in reducing your organisation’s carbon footprint.

Beyond these direct reductions, its impact extends into less tangible yet equally crucial realms beyond your business. This includes a reduction in transportation needs, decreased strain on roads, lower exhaust emissions, and even a reduction in traffic congestion—all resulting from reduced waste.

Improves Your Business Reputation

Demonstrating a proactive approach towards reducing your carbon footprint not only strengthens your organisation’s standing with employees, but also resonates positively with customers and suppliers. This, in turn, can result in heightened brand loyalty, an enhanced company image, and potentially increased sales.

While quantifying these benefits may be challenging, the reduction in carbon footprint should undeniably factor into your assessments of pigging system and product recovery ROI.

Contact the Pigging System and Product Recovery Specialists

Since 1995, HPS has been at the forefront of innovation in hygienic and sanitary product recovery systems. We have successfully deployed thousands of systems worldwide. With this extensive experience, our experts can recommend the best solution for your organisation, and help you accurately calculate costings, return on investment and pay back periods.

For more information on the return on investment a product recovery or pigging system could bring to your organisation, including detailed pigging system payback and ROI calculations, to talk to an HPS expert about the best system for your plant and process, or for pricing or cost information, please get in touch.