Pigging and Liquid Transfer Solutions

Explore our Core Solutions:

Pigging Systems for Process Applications

Designed for applications with frequent changeovers, viscous products, or high product value, HPS pigging systems recover up to 99.5% of product from pipelines. By minimising waste and cleaning fluid use, our systems help boost yield and sustainability across industries like food, beverage, cosmetics, homecare, and more.

Pigging Systems in More Detail

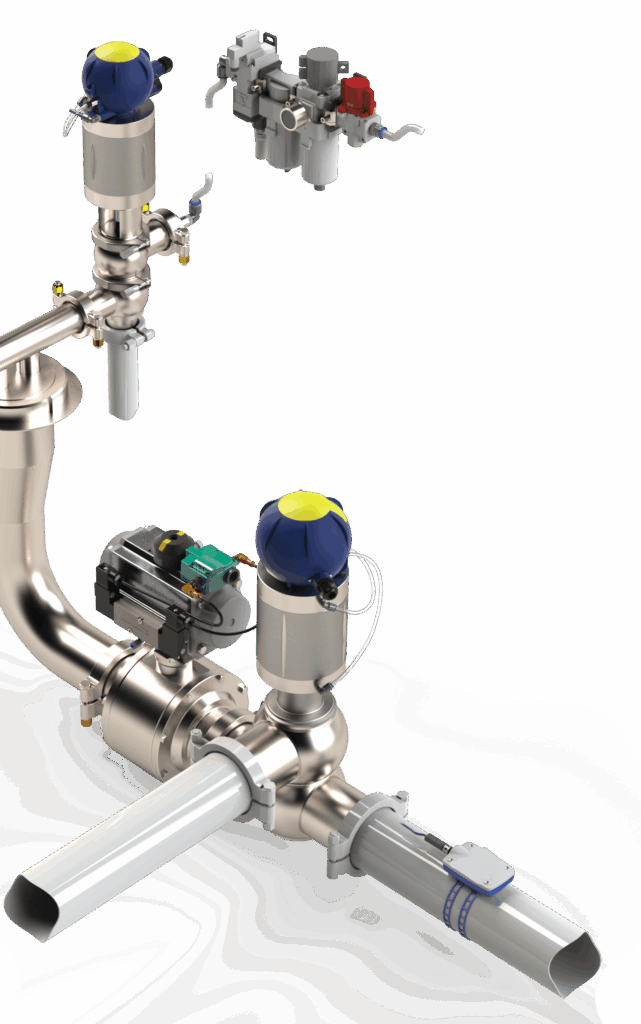

Liquid Transfer Routing Systems

HPS specialises in liquid transfer routing systems designed for processes with multiple sources and multiple destinations. Our industry-leading solutions, including the Automatrix Valve Manifold and the Rotomatrix Manifold, provide fully flexible product routing and recovery (pigging) from any source to any destination.

Liquid Transfer in More Detail

Pigging Equipment and Technical Services

We provide a complete range of pigging equipment and components including pigs, detectors, valves, automation, and engineering design. Every system is tailored to your process needs.

Explore Equipment and Services

Trusted by global brands

HPS pigging systems are used worldwide across a wide range of liquid processing industries. We support hygienic product recovery, transfer routing, and process optimisation for:

- Food & Beverages: sauces, dips, dairy, soft drinks, wine, beer, spirits

- Chocolate & Confectionery: Liquid chocolate, syrups, fillings, coatings

- Personal Care Liquids: shampoos, conditioners, body wash, toothpaste, deodorants

- Homecare Products: Detergents, surface cleaners, liquid soaps, disinfectants, varnishes, paints

- Industrial and Specialty Chemicals: Lubricants, adhesives, resins, solvents, and process chemicals

If it’s a pumped liquid or wet product, we can help recover and transfer it efficiently.

From spare pigs to fully managed, multi-site projects, HPS offer complete tailored solutions. With decades of industry experience, we have the technology, expertise, and support to meet your processing goals – now and in the future.

Tailored Systems. Proven Results.

Since 1995, HPS has worked with companies across the globe to design and deliver hygienic pigging and liquid transfer solutions that match their process goals, products, and infrastructure.

We offer a wide range of system configurations, including:

- Single pig systems

- Tank drop-off systems

- Dual pig systems

- Double pig systems

- Complex multi-source, multi-destinations

We manage every stage of delivery, from concept and design to commissioning and aftercare, with minimal disruption and maximum return on investment.

What Makes HPS Pigging Technology Different?

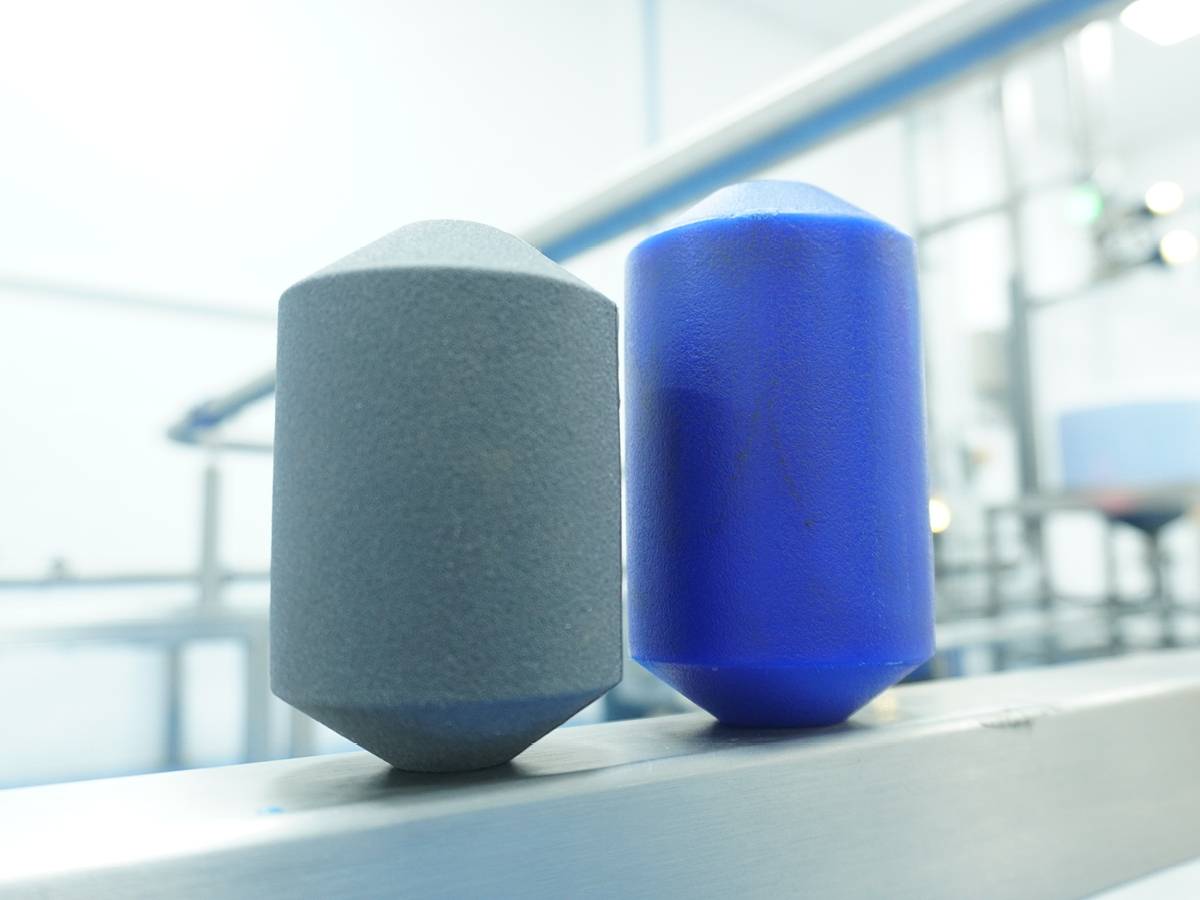

unique design of process pig

Our proprietary pigging technology uses no solid metal magnets. This eliminates the risks of shattering, fragmentation and subsequent product contamination. It is extremely safe while being highly flexible and delivering exceptional product recovery performance (greater than 99.5% on one pass).

no manual intervention

Our closed-loop, fully automatic pigging systems operate independently without manual intervention. The result assures best practice safety, productivity and reliability while delivering the highest level of microbiological cleanliness.

pig stays off-line until needed

We’ve designed our pigging system launch and receive stations so that our pigs stay off-line until you need them. So, they’re out of contact with your product unless they’re working. This ensures exceptionally efficient operation with minimal cross-contamination risks and the very highest standards of hygiene.

extensive safety features

Our pigging systems have extensive safety features to protect your staff, your equipment and your product. For example, our systems automatically decompress when the pig enters a launch station. This is without any mechanical or electronic control mechanism. It is highly unlikely to break or fail. It is, quite simply, superior to anything else on the market.

Easy Implementation

HPS systems are designed for seamless installation. Whether you are retrofitting into an existing line or designing a new plant, our solutions require minimal changes to your infrastructure.

Our team will help you maximise pigging returns while minimising disruption, downtime, and cost.

need help getting started?

We’ve developed a library of resources to guide you through the world of pigging and liquid product recovery.