If you work in liquid processing, transferring fluids or wet products through pipelines such as food, beverage, cosmetics, chemicals, or paint manufacturing, you’ve probably come across both pigging systems and CIP (Clean-In-Place) systems.

At HPS, we’re often asked:

- Do they do the same thing?

- Can one replace the other?

- Do you need both?

The short answer is no.

Pigging and CIP systems are not the same thing, and they are used for different purposes.

In fact, pigging and CIP systems serve very different functions.

However, they also go hand-in-hand.

When pigging and CIP technologies are used together, they can significantly improve efficiency, reduce waste, and enhance cleaning effectiveness.

In this article, we’ll break down the differences between pigging and CIP, how they work together, and when (and why) your operation might benefit from using both.

What Is a Pigging System?

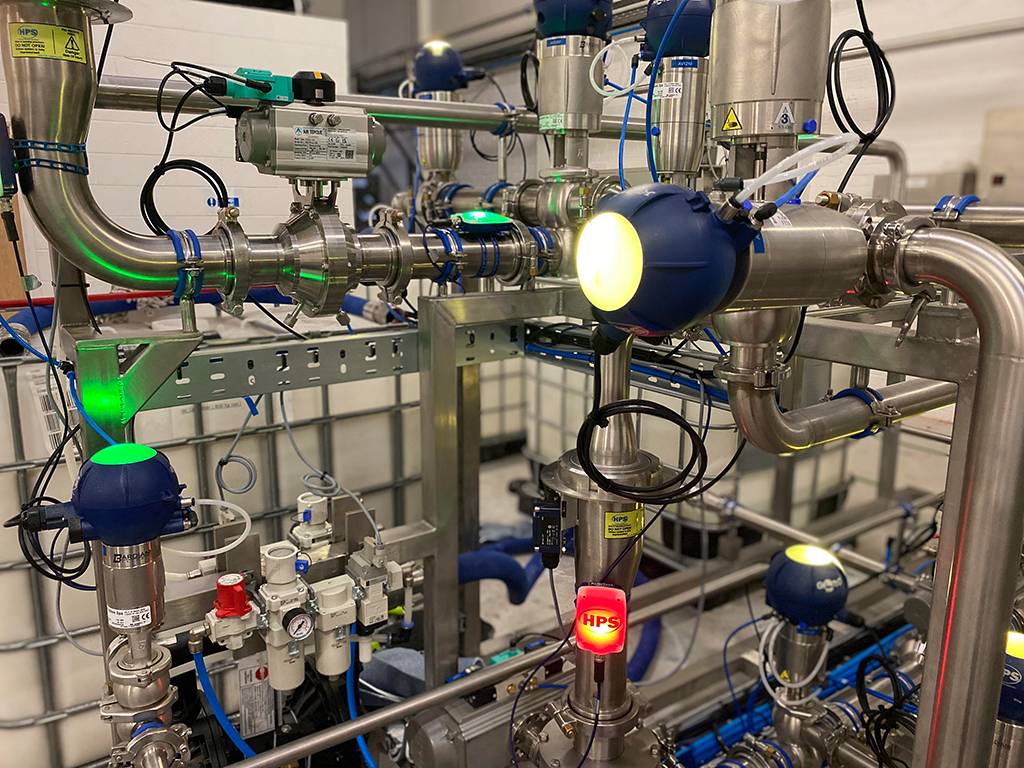

In process industries, a pigging system recovers residual product left in pipelines after a production run.

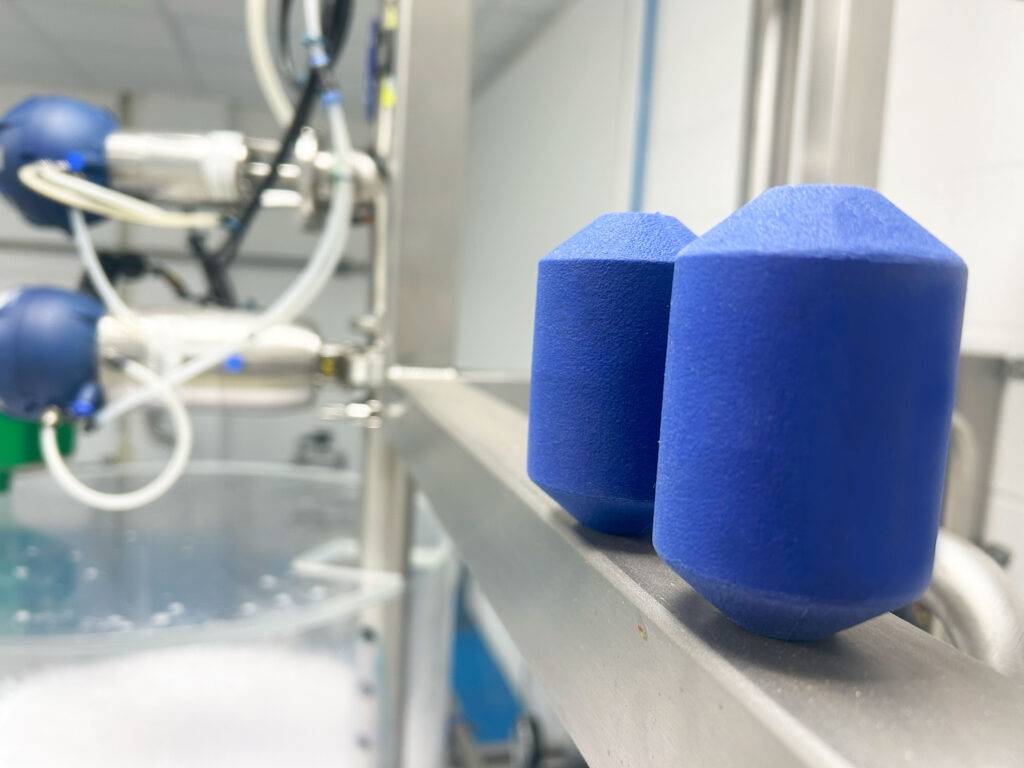

It uses a special projectile (called a pig) along with supporting components like launchers, receivers, valves, detection and automated control systems.

The pig is propelled through the pipe, typically by air, nitrogen, or water, and pushes product toward its destination.

Key Benefits of Pigging:

- Recovers up to 99.5% of sellable product

- Minimises product waste

- Reduces water and cleaning fluid usage

- Speeds up changeovers and production

While it has many benefits, Pigging is all about product recovery and process efficiency.

It’s important to note that pigs do not clean or sanitise – they remove and recover product.

What Is a CIP (Clean-In-Place) System?

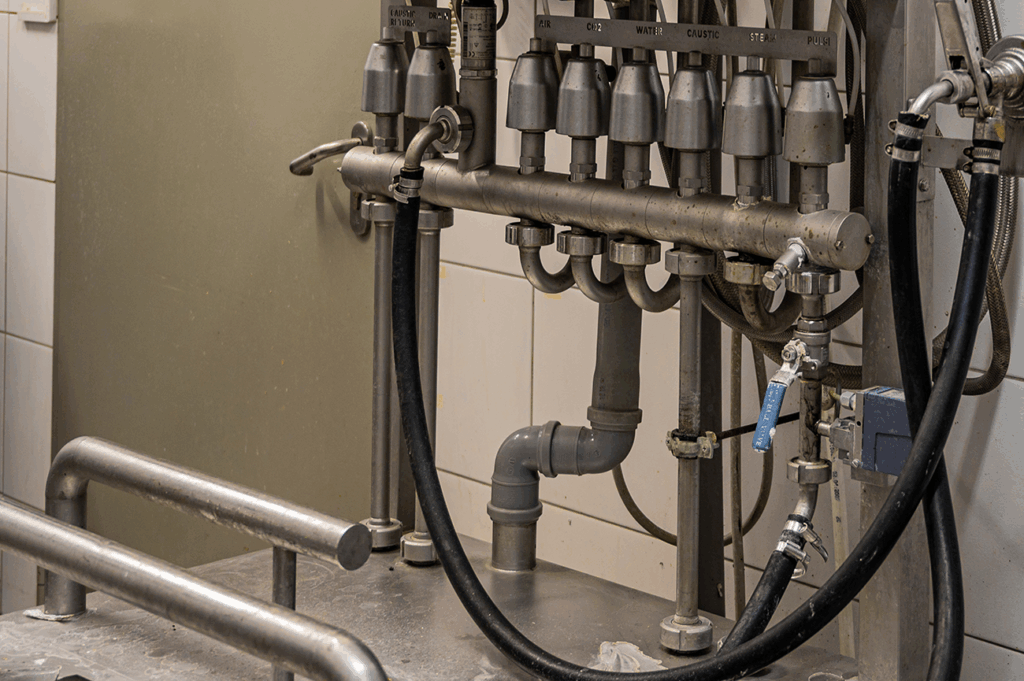

CIP systems are designed to clean the pipelines, valves, tanks, and other process equipment and components without dismantling them.

They use circulated water, detergents, and sanitisers to remove product residues, prevent microbial growth, and maintain hygienic conditions.

Key Benefits of CIP:

- Effective removal of soils and contaminants

- Maintains hygiene and regulatory compliance

- Can be fully automated

- Reduces the need for manual cleaning

CIP is all about sanitation and cleanliness.

Pigging vs CIP: Head-to-Head Comparison

Here’s how the two systems differ in purpose, operation, and value:

|

Feature |

Pigging System |

CIP System |

| Primary Function | Product Recovery | Cleaning, Sanitation |

| Medium Used | Pig and Air/Nitrogen/Water/Next product | Water, detergent, chemicals |

| Product Focus | Liquid products such as food products, beverages, shampoo, toothpaste, chemicals, paints and much more. | Waste, residue, microbial risk |

| Typical Use | Between batches or at the end of product runs, before Cleaning | After product run (and/or pigging) |

| Resource Use | Low (saves product, water, and chemicals) | High (uses water, energy, chemicals, however resource use can be less if combined with pigging) |

| Result | More yields, capacity, faster changeovers, less waste, less effluent. | Clean, compliant system |

Do You Need Both Pigging and CIP?

Pigging and CIP systems are not alternatives to one another, but complementary technologies.

Each serves a distinct purpose within liquid processing, and when used together, they significantly enhance overall efficiency and hygiene.

A typical sequence would follow this process:

- End of Production Run

- Pigging to recover residual, sellable product

- CIP to thoroughly clean and sanitise the system

Benefits of Pigging and CIP

Implementing pigging before CIP offers substantial operational advantages:

- Shorter CIP cycles due to reduced product residue

- Lower consumption of water, detergents, and cleaning chemicals

- Reduced environmental impact through minimised effluent

- Increased production uptime by accelerating changeovers and cleaning

Essentially, pigging optimises the CIP process, reducing its workload, cost, and duration, while helping manufacturers recover more product and reduce waste.

Integration Tip: HPS pigs, pigging equipment and pigging stations, including launchers and receivers, are designed for full CIP compatibility. These stations allow cleaning fluid or steam to circulate around the pig while in storage, ensuring safe, effective cleaning.

Common Misconceptions: Pigging Replaces CIP – or Vice Versa

Many manufacturers mistakenly believe that pigging can replace CIP, or that CIP makes pigging unnecessary. In reality, each system solves a different problem:

- Pigging recovers product and reduces waste.

- CIP removes contaminants and ensures hygienic compliance.

- Using only CIP means flushing significant amounts of valuable product away before cleaning.

While pigging significantly reduces waste and boosts efficiency, it’s not designed to replace cleaning or sanitisation. However it does make the cleaning process faster and more resource efficient.

When used together, pigging and CIP ensure maximum product recovery, hygiene, and overall process performance.

Importantly, HPS hygienic pigs can be safely steam-cleaned up to 250°C (482°F) and are fully compatible with CIP operations, making integration seamless and hygienic.

Real-World Applications: Where Both Systems Excel

In industries with frequent product changeovers, such as sauces, dairy, personal care, juice, and other liquids, pigging and CIP work hand-in-hand.

For instance:

- A juice manufacturer can use pigging to recover sellable product and reduce cross-flavour contamination, then follow with a short, targeted CIP cycle.

- A cosmetics producer may pig viscous creams or lotions from shared lines, then sanitise the system via CIP to meet GMP standards.

This combination enables manufacturers to maximise yield, reduce waste, ensure hygiene, and accelerate production changeovers.

HPS also supplies hygienic piggable valves that can be both cleaned in place and pigged, removing the need to compromise between recoverability and sanitation.

FAQs: Pigging vs CIP

Q: Can pigging replace CIP?

A: No. Pigging recovers product; CIP ensures cleanliness and hygiene. They serve different purposes.

Q: Which comes first – pigging or CIP?

A: Pigging is usually performed before CIP to remove product and reduce the cleaning load.

Q: Is pigging hygienic?

A: Yes. HPS hygienic pigging systems are designed for use in clean, sanitary environments and are compatible with CIP.

Final Thoughts: Pig First, Then Clean

Using CIP alone often means flushing away valuable, sellable product. When paired with pigging, the result is a more efficient, streamlined, and cost-effective process.

Together, pigging and CIP offer significant benefits: greater product recovery, faster changeovers, reduced water, chemical, and energy use and a fully sanitised systems ready for the next batch.

Whether you’re aiming to increase yields, shorten cleaning times, minimise waste, or improve sustainability, combining pigging with CIP is a smart, future-ready strategy.

Especially when you used Advanced Liquid Product Recovery Technology from HPS – as it’s name suggests, this is the benchmark and leading-edge of process pigging technology.

If you’re interested in adding pigging to your process? Send us a message, we’d love to help with your project.