What pigging is and how it works

What Is Pigging from HPS:

Experts in advanced Pigging Systems

Pigging technology has been around in different forms since the early part of the twentieth century.

Today, a wide variety of sectors, industries and applications that process liquids use pigging (more accurately described as ‘Liquid Product Recovery’ or ‘pipeline product recovery’) to reclaim liquids from pipelines and tubing. The primary purpose of pigging is to minimise waste, boost yields and capacity, and enhance the overall efficiency of manufacturing and production processes.

Despite it being in common use in factories and production facilities throughout the world, we’re often asked to give an explanation of what pigging is, what’s the purpose of pigging, and describe what pigging does.

SO WHAT IS PIGGING?

In the process industries, pigging refers to technology that uses specialist projectiles to recover, rather than waste, residual liquid in pipelines or industrial tubing. Originally developed for cleaning oil pipes, pigging has evolved into advanced, fully automated industrial pipeline product recovery and liquid transfer technology used today.

HPS are Hygienic and Sanitary Pipeline Product Recovery Experts.

Where Is Pigging Used?

If you drink wine, beer, spirits, fruit juices, cola or other types of soft drinks; if you eat chocolate, sweets, candy, yoghurt, soup, honey, sauces, ready meals or dips; or if you use paint, varnish, shampoo, shaving gel, cosmetics, toothpaste, washing up liquid or other household product, then the chances are you’ve drunk, eaten or used something that’s been “pigged”. In other words, pigging has been used at some point during its processing or production.

HOW PIGGING WORKS

In its simplest form, a pigging system consists of a solid projectile or plug (the ‘pig’) with a diameter slightly larger than the pipeline or tubing that is transporting the liquid. Pigging works by introducing this pig into the pipeline and pushing it through the pipe. Sometimes it is introduced manually but more commonly automatically. Pigs are introduced, housed and returned using pig launchers and pig receivers. After pigging, liquid is then collected or continues to be processed.

Why Do Companies Use Pigging?

The main reason organisations in process industries use it is to recover products, which increases yields and reduces waste. Process industries also use pigging to remove nearly all residual product from the inside of pipes and tubing, which in turn reduces the use of cleaning fluids, uses less water, saves time, improves process efficiency and ultimately increases profits. In addition, because pipeline product recovery using pigging saves resources, it also helps towards sustainability.

More detail on

How pigging works

-

What happens during the pigging process?

To ‘pig’ a system, HPS pigs are propelled through the pipe by pressurizing the pipe work behind it. There are different ways to propel pigs, but usually compressed air, carbon dioxide (CO2), nitrogen, clean water or even the next product (depending on the application) provide the pressure. Instead of being flushed to drain, waste treatment or collection areas, the liquid residue in the pipe is recovered: pushed by the pig and forced to the destination filler or tank to continue processing along with the rest of the product.

-

How fast is the pigging process?

What many people don’t realise is that pigging is an extremely quick process. The precise speed at which a pig travels depends on a number of factors; however, the process is nearly always a lot quicker than many people think. This is great because it saves time and labour with reduced CIP and speeds up changeovers. Here’s a video which shows how fast a pig travels through a pipeline or tube. See how there’s no product left on the clear tube after pigging and how fast the pig travels; it’s all done in an instant!

-

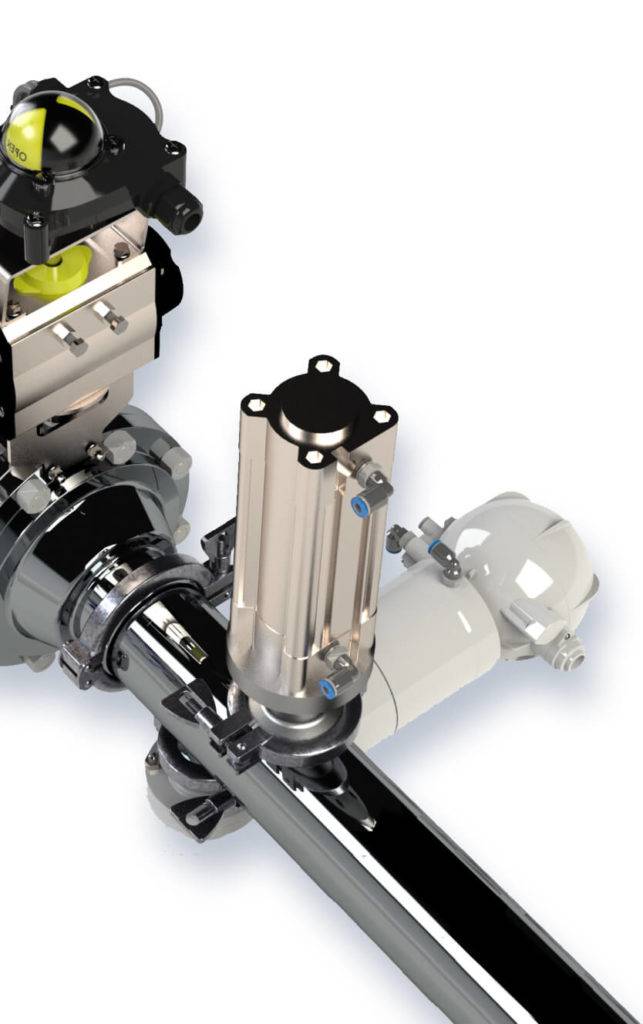

What are the parts and components of pigging systems?

A pigging system is made up of a variety of different parts and components. These include pig launchers, receivers, detectors, storage, housings, propellant sources, PLCs, HMI’s, control software, and various valves, supports and fittings.

Pigging system components are often fitted on existing process equipment or can be built into new designs. However, the most important component is the pig itself. The operational efficiency, effectiveness and ultimately the success of a pigging project depends on a reliable, high-performance, well designed, good quality pig.

-

What are the key industries benefiting from pigging?

There’s a massive range of liquid products and processes that use pigging. Examples of these include food and beverages (which use hygienic or sanitary pigs and hygienic or sanitary tubing), as well as household, personal care, cosmetics, paints and pet food production.

While pigging is used in a wide variety of different industries and sectors to achieve different results and goals, the main purpose of pigging usually centres on product recovery, product transfer, environmental sustainability and operational efficiency.

-

Is pigging used in industrial processes?

While many industrial process applications use pigging, it’s also used in utility industries, such as oil, gas and water. However, while the principles are similar, there are big differences between industrial process pigging and utility pigging.

-

Are pigging system designed with automatic control?

Most HPS pigging systems are either partly or fully automated. Pigging systems with fully automated pigging process control have a wide range of benefits. This includes increasing process speed, productivity, and efficiency. Automation also enhances safety and decreases the chances of human error.

-

Pigging in Practice

Here’s a typical example to illustrate why many industrial processes use pigging.

Imagine a company in the business of manufacturing paint, where they need to switch paint types or colours multiple times a day while using the same pipeline. In such transitions, traces of the previous paint run invariably remain in the pipeline, clinging to its walls or residing in other sections.

It’s imperative to eliminate all remnants of the previous product before initiating the changeover. This has to be removed to prevent any contamination of the subsequent product. More significantly, this residual product is perfectly usable. So, if it’s flushed away, it’s wasted rather than processed, packaged or sold. This practice is not only detrimental to sustainability and the environment but also incurs unnecessary costs.

Without a pigging process, the pipe or tube would typically be flushed through using water or other cleaning fluid (and some cleaning fluids are highly toxic). Not only does this take time, labour and uses a lot of water and cleaning fluid, it results in the fluid that stays in the pipe being flushed to waste. Pigging saves this product in useable form. HPS pigs typically recover up to 99.5% of product!

While we’ve used paint as an example, it’s important to note that pigging is not limited to this industry. A wide array of liquid products and processes benefit from pigging technology.

TYPICAL PIGGING APPLICATIONS

SINGLE PIG PIGGING SYSTEMS

Single pig pigging systems are a highly efficient and versatile pigging configuration. Here are some common examples (but not limited to):

- Single Source to Multiple Destinations

- Single Pig Three-Way Launch Water Push

- T-Launch System

- Multiple Sources to a Single Destination

DOUBLE-PIG PIGGING SYSTEMS

Double-pig pigging systems are a specialised form of pigging technology engineered to minimise the risk of product exposure to air during processing.

This makes them particularly well-suited for handling products such as beer, wine, and foam gels, where contact with air can cause degradation, foaming, or unwanted aeration.

DUAL-PIG PIGGING SYSTEMS

Dual-pig pigging systems are a specialist type of pigging system, typically used by manufacturers looking to incorporate the first step of the cleaning process into their product transfer and pigging operations.

Case STudy on pigging systems

saving a consumer goods company around 160 gallons of a popular homecare product

Discover the impact of pigging. See how pigging systems make a significant impact on consumer goods production. Our automated pigging solutions not only cut waste but also enhance efficiency, accelerate changeovers, and improve environmental sustainability in homecare liquid manufacturing.

Use a Specialist

Pigs are dense objects working in pressurised systems that travel through pipes at high speed. So, pigging system safety must be given the highest priority to mitigate and minimise risks.

There are many physical, electronic and procedural safety measures you can put in place to do this. The most important thing is to use an experienced provider like HPS. Our systems have exceptionally high levels of safety and an excellent track record.

While the principles of pigging are fairly straightforward, achieving success in designing, implementing, and commissioning an effective pigging system requires years of experience and a profound level of expertise.

It demands a nuanced understanding of how pigging works. This is precisely why, when considering a pigging solution for your company, it’s imperative to collaborate with a specialist company like HPS Product Recovery Solutions.

why COMPANIES USE pigging

HERE’s WHY YOU SHOULD BE pigging

increased yields and margins

Instead of flushing residual product to waste, pigging systems mean you can continue to process it, or pack, store or sell it.

reduced waste processing

By increasing product yields through pigging, there’s less product to send to waste. In addition, the cleaning and changeover processes also use less cleaning fluids and water.

IMPROVED ENVIRONMENTAL SUSTAINABILITY

Because pigging saves product, cleaning agents and water, it’s much kinder to the environment. Not only are you using less overall, but there’s also less waste to treat, saving resources and energy, as well as less waste to transport, so fewer trucks on the road going to treatment plants and disposal facilities.

Increased efficiency and PRODUCTIVITY

Pigging systems improve productivity and efficiency. This is through increased yields, higher capacity, faster changeover times, reduced flushing and so on.